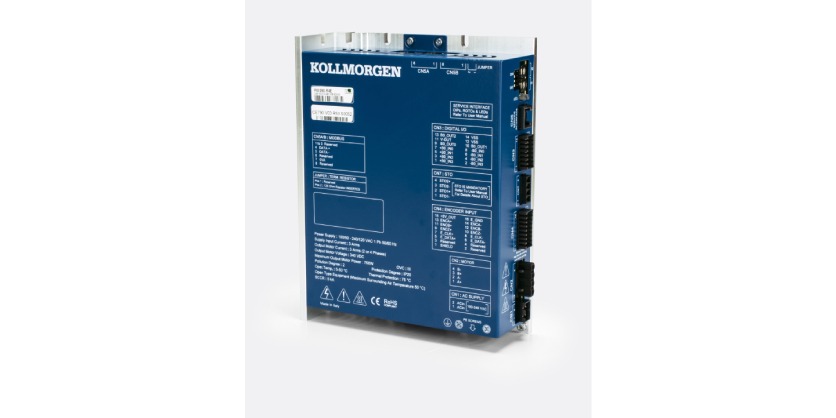

Kollmorgen Expands P8000 Series with P80360 Stepper Drive

January 2, 2025

Kollmorgen has announced the launch of the P80360 stepper drive, the latest addition to its P8000 series. This new drive brings advanced functionality to the series, including closed-loop position control and full programmability, combining the precision of servo systems with the reliability and simplicity of stepper technology.

Key Features of the P80360 Stepper Drive

- Stepless Control Technology: Like other drives in the P8000 series, the P80360 delivers smooth, quiet operation and consistent performance across a broad speed range.

- Closed-Loop Position Control: Incorporates encoder feedback to correct overshoot or undershoot errors automatically, enhancing precision and reducing risks of scrap or equipment damage. This feature also improves energy efficiency by optimizing motor operation and reducing heat generation.

- Programmability: Fully programmable through Kollmorgen Space software, enabling point-to-point movements and complex motion sequences without requiring an external PLC or indexer.

- Ease of Setup: Includes a Motor Wizard tool for quick machine setup with Kollmorgen motors, requiring only basic input parameters such as velocity and acceleration.

Applications and Compatibility

The P80360 stepper drive supports stepper motors with phase currents up to 3.0 Arms (4.2Apk) and is suitable for a wide range of applications, including:

- Labeling systems

- Indexing tables

- CNC machines

- XYZ gantry systems (e.g., 3D printers)

- Packaging machines

- Medical laboratory equipment

- Pumps

Kollmorgen’s Commitment to Quality

The P8000 series, including the P80360, is certified for CE, RoHS, and REACH standards and offers unparalleled precision for motors powered by 100 to 240 VAC single-phase power.

More Information

For more information, visit https://www.electromate.com/p80360-stepper-drive/ . For further information, please contact:

Warren Osak sales@electromate.com Toll Free Phone: 877-737-8698 www.electromate.com

Related Story

Electromate Recertified as a ‘Great Place To Work’ for 2024

Electromate Inc. is proud to be Recertified™ by Great Place To Work® for the 8th year in a row. The prestigious award is based entirely on what current employees say about their experience working at Electromate. This year, 86% of employees said Electromate is a great place To Work – 26 points higher than the typical Canadian company.