celduc Brings You 7 Reasons to Use Solid State Relays

November 26, 2024

A solid state relay is ideal when fast, frequent switching is required. Throughout this article, celduc will give you the key advantages of using a solid state relay.

1- SSRs have an infinite lifespan for a long service life

SSRs do not have any moving mechanical parts so they are not subject to any contact failure, mechanical strain or corrosion. An SSR has an average lifespan of millions of cycles with no deterioration in performance. But in order to benefit from a solid state relay’s infinite lifespan, the SSR needs to be used properly.

One of the problems that arise when using solid state relays is the substantial amount of residual electrical resistance. This resistance generates heat which can be combatted by the use of a heatsink. Without the heatsink, the lifespan of the SSR will be reduced drastically. So it is very important to consider purchasing a heatsink and SSR together. Fortunately, several of the celduc’s solid state relays sold already come equipped with heatsinks, they are « ready to use ».

When used correctly, solid state relays are the ideal solution for applications that require frequent operations.

2- They are energy-saving thanks to a very low power consumption

Solid state relays and contactors require very little input power “coil current” to switch strong power loads.

Since the relay does not have to energize a coil and physically open and close contacts, it actually consumes 75% less power than EMRs.

3- They are silent

SSRs use electronic circuits to provide switching soi t means Solid state switching solutions make no acoustical noise when the output contacts change state : they have completely silent switching operation. This is a highly desirable feature in various commercial and medical applications.

4- They are resistant to Shocks and vibrations

Solid State Relays have no moving parts and are entirely enclosed in housing, they are well-suited for harsh environment applications. In addition, there is no risk of accidental switching with SSR Technology as they will not bounce electrically or mechanically. This makes them highly susceptible to perform in high vibration environments, such as railway & rolling stock application.

5- They allow very high switching frequency for very accurate adjustement

Solid State Relays switch on/off faster because there are no physical parts to move. This means power to a load can be applied and removed very quickly and precisely, which is especially important for applications that requires quick on-off switching. This is the case for temperature control where low switching frequency will limit the accuracy.

6- They provide special controls and diagnostics

Solid State Relays offer different types of controls (specific choice of switching time) and possible diagnostic features.

7- They allow various mounting configurations

From the hockey puck to the 22.5mm relay. There are different package styles allowing the Solid State Relays to be mounted in several different ways, such as : panel mount, DIN Rail mount and PCB mount.

Solid-state relays are the way to go for many applications.

More Information

To learn more about celduc’s wide range of SSR products that offer the advantages they have discussed in this article, visit www.e-catalogue.celduc-relais.com

Related Story

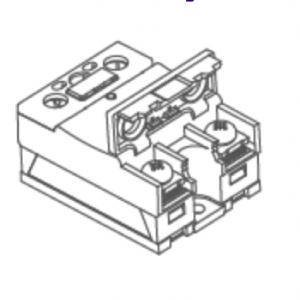

XKLD31006 DC Solid State Relay with Built-In Protections

celduc’s XKLD31006 is EN50155 certified and is an ideal choice for use in the demanding rolling stock environment as well as in harsh industrial applications.

Their XKLD31006 has recently obtained railway certification after a series of rigorous tests, designed to simulate the extreme conditions in railway environment: such as voltage variations, power interruptions, and supply changeover, but also environmental disturbances, like vibrations, shocks, and extreme temperatures.