After the Olympics in Paris, Now the WorldSkills in Lyon

September 9, 2024

Festo promotes many facets of the 62 competitions at the 47th WorldSkills Championships

The Olympic Games in Paris are over – now another French metropolis is taking center stage: Lyon will host the 47th WorldSkills from September 10 to 15, 2024. The WorldSkills Championships will bring together more than 1,500 young people from over 65 countries and regions to compete in 62 competitions.

Every two years since 1950, young skilled workers from all over the world have competed in the WorldSkills Championships. They measure their skills in the individual trades in accordance with the demanding WorldSkills standards. The participants qualify beforehand through a national selection process.

Industry-related learning solutions as competition equipment

During the four days of the competition, the teams of young skilled workers work on solutions for highly technical tasks using learning systems provided by Festo Didactic. Festo has been a Global Industry Partner of WorldSkills since 1991. Global Industry Partners play a key role in the cooperation between industry, education, and political decision-makers.

Their common goal is to improve the education and recognition of skilled professionals around the world. Festo Didactic offers state-of-the-art industry-related learning solutions and is a sponsor for the future-oriented and sustainable WorldSkills competitions Mechatronics, Industry 4.0, Water Technology, Renewable Energies. It is also a pneumatics and software supplier for the competition disciplines Industrial Mechanics and Industrial Controls.

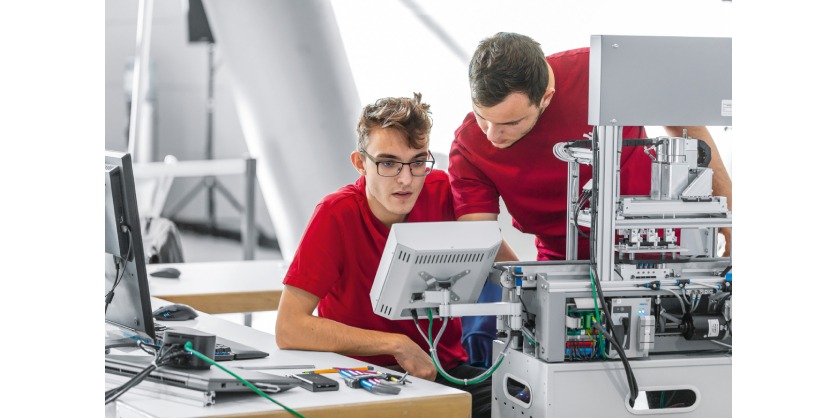

Festo apprentices at the WorldSkills competition

Mechatronics technicians Paul Schunck and Julian Winter from the Festo plant in St. Ingbert-Rohrbach, Saarland, won the German championship in the “Industry 4.0” discipline last year. The reward: the two trainees are allowed to represent the German colors at WorldSkills and compete for the world championship title of the world’s best trainees. In the Industry 4.0 competition, the trainees must build a mechatronic production system with a particular focus on information security.

Accompanying WorldSkills Conference

The WorldSkills Conference 2024 will take place alongside the competitions. On 11 and 12 September, the conference will provide a discussion platform for political and industrial decision-makers, education providers and young people on topics such as excellence in vocational education and training, gender segregation in skills, the transition to a green economy with green skills, skills development for fragile economies, digitalization, and artificial intelligence.

Dr. Oliver Niese, CEO of Festo Didactic SE, underlines the importance of high-quality vocational training programs for the economy and the preparation for the changes in the labor market, especially regarding the green transformation and the application of artificial intelligence: “WorldSkills plays a crucial role in integrating vocational training into the global agenda for sustainable development and in providing the necessary skills.”

Appendix: Explanations of some WorldSkills competitions

Discipline 04 Mechatronics

The mechatronics competition has been held on Festo Didactic’s Modular Production Systems MPS since it was first held in 1991. The concept is based on competence-oriented training and further education in mechatronics and automation technology as well as industrial proximity and robustness of the equipment. The high modularity of the system makes it possible to combine components, modules and stations to create a production line tailored to specific learning objectives and scenarios.

Discipline 48 Industry 4.0

The teams in the competition develop their solutions on the CP Lab system from Festo Didactic. This cyber-physical learning and research platform provides basic and in-depth knowledge of digital, fully automated production technologies as well as the design and programming of digital plant networks. The individual modules of the platforms model the stations of real production plants. This creates ideal conditions for learning many technologies such as AI, MES, IT security and energy management.

Discipline 55 Water Technology

This is only the second time that the Water Technology competition has been officially included in the WorldSkills program. Competitors work on the modular learning system EDS Water Management (Environmental Discovery System), which represents the core processes of a water and wastewater treatment plant in the form of a water cycle from the source to the treatment plant and back again. In view of today’s global challenges in terms of global warming and water scarcity, specialists such as water technologists are more than in demand. The official competition equipment, which is based on the defined WorldSkills standards, also comes from Festo Didactic in this discipline.

Discipline 62 Renewable energies

Festo Didactic is providing its Nacelle wind turbine learning system as competition equipment. Future wind technicians use this system to prepare for real operating, troubleshooting and maintenance situations. In close cooperation with its members and partners, the umbrella organization WorldSkills International is thus responding to the changing situation on the labour market and, by introducing new disciplines, is specifically supporting the training of skilled workers in future professions as well as the topic of sustainability.

Festo Didactic is a leading provider of technical training and further education. The product and service portfolio offers customers integrated educational solutions in industrial automation topics. The wide range of products and services are aimed at vocational schools and universities, research centers and industrial customers. Festo Didactic is part of the globally oriented, independent family-owned company Festo with headquarters in Esslingen a. N. The 760 employees of Festo Didactic in 61 Festo national companies generated sales of EUR 140 million in 2022.

Related Story

Festo Didactic at the Forefront of Developing Canada’s Future Work Force

With Canadian manufacturing suffering from a growing labour shortage, the participation of industry in skills development is emerging as a vital component in hiring and retention. The needs are stark: The Canadian Exporters and Manufacturers Association says almost 40% of its members have jobs they can’t fill. Five years from now, 60% expect to be short-staffed, especially when it comes to skilled trades. Statistics Canada forecasts the country’s labour force growth rate will remain below 0.2% for the rest of the decade, below replacement levels.