Transforming the World Through Automation: FANUC’s Innovative Solutions at IMTS 2024

September 3, 2024

New Robots, Cobots, Materials Joining and Controller Technologies to Debut Sept. 9-14

FANUC, a global industrial automation leader, is set to unveil its latest lineup of robots, cobots, factory automation offerings and machining solutions, while introducing two new controller technologies at the International Manufacturing Technology Show (IMTS) 2024.

“Whether you’re a small shop or a high-volume producer, we have the automated manufacturing solutions to help you grow and sustain your business into the future,” says Mike Cicco, CEO, FANUC America. “At IMTS 2024, we’re excited to showcase two new controllers powering that evolution—the R-50iA Robot Controller and 500i-A CNC—both offering powerful performance, optimized efficiency and more security than ever before.”

Showcasing the company’s cutting-edge automation solutions, the FANUC America booth will include a wide range of collaborative robots, allowing manufacturers reimagined flexibility in shared workspaces. From collaborative machine tending and heavy payload handling robots, to arc and friction stir welding demonstrations, brand-new demonstrations will also be available—including several powered by the all-new R-50iA Controller—designed to maximize performance and ease of use while offering enhanced cyber security.

FANUC America will also introduce North American audiences to the FANUC Series 500i-A CNC. This new control series advances machining performance with its 5-axis integrated technology and faster processing speeds. The control’s new features are designed to support both machine tool builders and CNC users with their evolving needs for easier operations, more security and optimized efficiency.

On display in Booth #338919, IMTS attendees can view the following new technologies in action:

Collaborative Robot Zone

- With an extensive line up of industrial collaborative robots that are helping to solve once-complicated issues inside plants and warehouses, FANUC America’s technologies are safe, flexible, quick to implement and easy to program. A diverse range of CRX cobots—offering payloads up to 50kg and reach up to 1,889mm—will be on display, including the world’s first explosion-proof paint cobot: the new CRX-10iA/L Paint. Hands-on demonstrations will allow attendees to experience the CRX-10iA/L Paint cobot’s smooth and easy path generation, and ease of setup, programming and use, even with little to no robotic experience in the painting, powder and/or gel coating with fiberglass reinforcement industries.

Innovations in Materials Joining

- Debuting at IMTS, the new M-950iA/500 heavyweight robot features a wider range of motion, offering an impressive 500 kg payload capacity and 2,830 mm reach, showcased in a new friction stir welding demonstration featuring StirRob Friction Stir Welding Head by FPT Industrie.Also being shown for the first time in the U.S., the new M800/60-20B with High-Speed Laser Cutting, FANUC’s next-gen, high-accuracy industrial robot connected to a TRUFiber 4001 P and Lasermech FiberCUT STa to showcase high speed laser cutting. Cut holes are generated with Shape Gen software for easy single point teaching. Innovative welding applications, including arc and spot welding, will also be on display.

New Controllers Deliver Powerful Performance

- Offering enhanced performance, optimized efficiency and more security, FANUC America debuts two new controllers in North America—the R-50iA robot controller and the 500i-A CNC advancing machine performance. Built on 50 years of automation expertise, both systems offer industry-leading ease of use and energy savings.The world’s* first robot controller to offer cyber security, the R-50iA is an intelligent and compact solution delivering higher precision for exceptional robot path control, built-in vision enhancements and third-party certification for international cyber security: IEC62443-4-1 and 4-2, offering multiple layers of defense to secure data exchange. The new R-50iA controller is available in three sizes including the R-50iA Mate, R-50iA A-Cabinet, and the R-50iA B-Cabinet. Additionally, the FANUC Series 500i-A CNC advances machine performance with 5-axis integrated technology and supports both machine tool builders and CNC users through easier operations, energy savings, and increased processing power. This higher performance helps deliver lower cycle times with faster speeds and improved productivity.

High-Performing Machining Solutions

- FANUC’s Factory Automation demonstrations will show how our new CNC products are taking the machining world to the next level. Showcasing the new FANUC Series 500i-A CNC, FANUC’s “Ghost Machine” demo will display the cutting simulation of the FANUC Hero, a figure comprised of all FANUC products – CNCs, robots and ROBODRILLs. Each side will show a different POV simulation of the cutting. FANUC’s Smart Digital Twin will also be on display, demonstrating how our software is used to digitize and innovate the machining process.

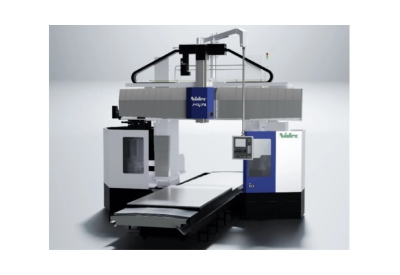

Vertical Machining Centers

- The company will unveil the latest addition to FANUC’s ROBODRILL vertical machining center (VMC) lineup, the new α-D28LiB5ADV Plus Y500. A series of demos will show how this new VMC offers more advantages to any production machine shop by featuring a larger table, shorter drilling and tapping cycles as well as an increased tool storage capacity coupled with faster tool changes.

Connected Technologies

- FANUC’s IoT offerings, ZDT and MT-Linki, allow both robotics and machine tool users the ability to use advanced analytics to drive smarter, faster business decisions for industrial companies. We’ll be showing how these products connect all the FANUC equipment in our own booth and the insights they provide.

As a part of its commitment to transform the world through automation, FANUC recently announced the establishment of the $1 million FANUC Automation Endowed Scholarship Fund in collaboration with the SME Education Foundation. As the largest automation scholarship in SME Education Foundation history, this initiative will foster the next generation of skilled professionals in advanced manufacturing and automation.

“We’re excited to return to the IMTS Smartforce Student Summit this year and continue our work to advance the education of future automation technicians and engineers,” says Paul Aiello, Director of Education for FANUC America. “Our industry is facing critical labor challenges, but by helping to fund automation training and certification for students, we’re creating a win-win scenario for today’s students and employers.”

Learn more about FANUC at IMTS 2024.

See FANUC Experts

Session: Successful Automation Strategies: Fast, Wide Scale Implementation for Small or Global Organizations

Panelist: Jerry Perez, Executive Director of Global Accounts, FANUC America

Date: Wednesday, Sept. 11, 11:00-11:55 AM

Location: W192-B

More Information

Learn more here.

Related Story

FANUC America Unveils New $110 Million Robotics and Automation Campus

FANUC America, a global leader in robotics and automation systems, has officially unveiled its new 650,000 square foot West Campus facility in Auburn Hills, Michigan. The expansion increases the footprint in Michigan to over 2 million square feet and is part of FANUC America’s strategic investment plan to support and advance industrial automation in North America. The West Campus represents a $110 million investment built on 67 acres of land.