SEW-Eurodrive Is Your Complete Source for Motion Control

August 12, 2024

By Krystie Johnston

SEW-Eurodrive specializes in custom, scalable drive solutions that focus on meeting the needs of customers today – and into the future. SEW-Eurodrive’s decentralized variable frequency drives combine power, communications, integration, and support all-in-one, saving you time and money. They have this and so much more to offer.

SEW-Eurodrive has set the trends and standards in drive engineering for years. Their universal concept of gearmotors, control systems, software, service, and extensive accessories are the cornerstone of many industrial motion systems. Dominique Salvail, Product Specialist, Factory Automation Solutions at SEW-Eurodrive, discusses how they have everything you need for your motion control application, and highlights how their decentralized VFDs can save you time and money.

SEW-Eurodrive’s decentralized drive technology offers compact drive units, decentralized inverters, and motion controllers for field use – everything you need to get up and running quickly. And, with its modular construction, everything can be easily combined and recombined as needed, making them scalable and future proof.

Salvail explains that a decentralized VFD is a motor control unit that is removed from a central control cabinet and distributed out on a machine, close to the motors, offering several benefits. First, it makes it possible to have a smaller cabinet or control panel, and second, provides a much simpler wiring architecture. Moreover, this setup also makes the motion system more efficient and flexible. For example, a decentralized VFD makes it easier to add a conveyor or other function in the future.

SEW-Eurodrive’s decentralized drive technology has everything you need

What makes SEW-Eurodrive’s decentralized VFDs a good option for these motion applications are its integrated communication and power and its modularity. Salvail says that with its single power and communication cable, there are only two cables that need to connect from motor to motor compared to the multiple cables a traditional motion setup requires to connect things like power, brake control, encoders, IO, etc. And it is always the same unit controlling the motors that slide underneath – both of which are features that save time and money in the long run.

Decentralized VFDs may appear to be more expensive than traditional systems at first glance, Salvail admits, but the fact is they save money in terms of components and time. “The components can be a bit more expensive, but, if a real cost-saving analysis is done, customers will see savings at the panel, fewer wires, little-to-no cable tray result in savings for parts, people, and time with faster commissioning.” With the average cost of electrical cables at $13/meter on average, significant savings are possible.

Salvail points out that a real cost analysis needs to include the total cost of all peripheral components that are required for an application where the VFD(s) are kept in a cabinet or control panel. For instance, motion applications can require multiple VFDs inside the cabinet. Salvail has seen upwards of twenty or more, all of which require extensive cabling for power, brake control, encoders, IO, and more.

Comparatively, SEW-Eurodrive’s decentralized VFD setup requires only one cable for power and communication, significantly reducing the number of parts to purchase, install, commission, maintain, and replace.

Moreover, this configuration makes it easier for engineers and OEMs to design machines and motion systems, facilitating smoother factory acceptance (FAT) and site acceptance tests (SAT). All this considered, a decentralized VFD application does result in savings of money and time, features Salvail knows end users appreciate.

The right drive for any motion application

SEW-Eurodrive invests in research and development to bring you the most reliable and efficient products for your motion application. Salvail knows that decentralized VFDs are not always the best option for every application. When he works with customers to configure a drive, he takes the time to understand what their application is, and to find a solution that works for them.

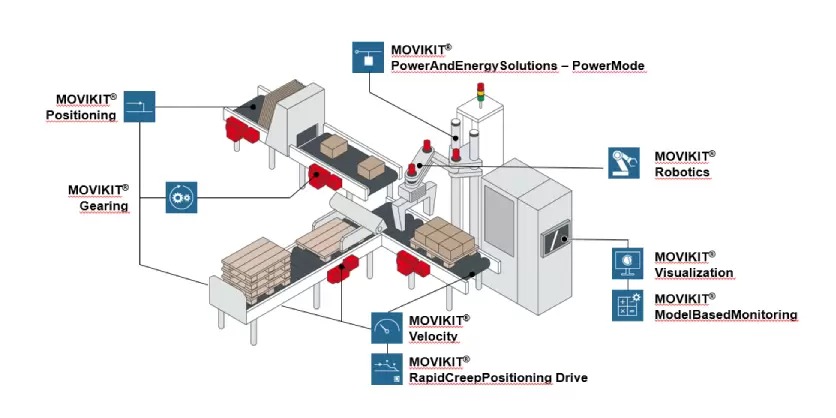

“Decentralized is not for every application. Sometimes, it is better to have the VFD stay in a cabinet for different reasons, like synchronized motion control. For these situations, we have a controller (UHX) plus a VFD that includes one of our software modules from the MOVIKIT® library. We have solutions for these applications that will still save time and money as well,” he says.

MOVIKIT® is one solution in their portfolio that ensures your motion application is scalable, future-proof, and easy – regardless of where your VDF lies in relation to the motor. MOVIKIT® is their software modules that are used for everything from drive functions through to complex motion control functions. Salvail explains that these software modules are already pre-programmed for specific motion tasks, such as speed control and positioning, and that customers can take advantage of them by simply entering their parameters from their MOVISUITE® engineering software.

These modules are just one solution in SEW-Eurodrive’s portfolio of solutions for your motion application. “We have been talking about decentralized but we have two offerings; VFD direct on the motor or remote VFD that can be next to motor on conveyors or wall mounted as needed. All our decentralized VFDs have the option of IO on them that uses the communication cable to and from the PLC or controller.”

“We are a solution-based supplier, so that means that we can select the right configuration in relation to each application. We can propose a decentralized setup or configure the VFD in panel if that is a better solution. A mix of both can be proposed. Workbench helps in those situations,” says Salvail.

A solutions provider first, customer focused always

SEW-Eurodrive has so much more to offer than just drives. They can supply every component required for your motion application, including the gearbox, motor, VFD, controller, and human machine interface (HMI). And customization is their specialty. Their recent product brochure was released earlier this year and showcases their full offering.

Salvail appreciates their MOVILINK® DDI digital motor interface that transmits power, brake, and diagnostic data from the motor to the VFD and then to the PLC/controller – all in one cable! DDI is yet another way that Sew-Eurodrive is saving you time and money at installation and startup, while ensuring your operations are scalable and ready for the future.

SEW-Eurodrive goes above and beyond for their customers every day. Their VFD landing page provides the option to configure your drive for your application using their drive configurator software, or you can opt for what they call ‘Red Glover Service’ and work with one of their specialists like Salvail to configure the solution that best suits your applications and needs. No matter where you are in Canada or what your industry is, SEW-Eurodrive is there for you.

With almost 100 years of experience, they understand the challenges your business and industry endure – and how to optimize your drive application to overcome them.

“We have different tools to help customers do their own drive selection. On our website, you can easily select a series and use tabs to select options, and the configurator will propose units accordingly. Registered customers can even request a quote from the platform. Workbench is another tool that is even more specific for selecting products – from controls to motors and gearboxes at engineering or design level,” says Salvail. “We have a well-established team of customer and technical engineering support there to help customers select what they need.”

In fact, SEW-Eurodrive has an emergency sales and support offering that sets the bar on customer service. From coast to coast to coast, SEW-Eurodrive has support available 24/7/365. Salvail says their engineering team can log in with customers and assist them in real time, making it easy to troubleshoot problems, even remotely. He adds that all their products now have QR codes to facilitate product support quickly and easily – even when your drive is running! And they provide quick shipping from every production location so you can get back up and running in a flash in the event of a breakdown.

Conclusion

SEW-Eurodrive offers more than motors and gear boxes. They specialize in customizable, scalable drive solutions that focus on meeting the needs of their customers today – and into the future. By combining power, communications, integration, and support into one system, SEW-Eurodrive’s decentralized VFDs are an excellent choice for your motion application because they save you time and money. If a decentralized setup is not the right fit for your application, do not worry; they have a drive for that too.

Interested in learning more? Visit their VFD landing page today and see what they have to offer.

Related Story

Why Choose SEW-EURODRIVE VFD’S?

SEW-EURODRIVE’s decentralized drive technology has everything you need – compact drive units, decentralized inverters and motion controllers for field use – and everything can be easily combined and recombined as required. This is all possible because the standardized control and communication architecture forms the perfect pairing!