Comau Presents Its New Cell Formation and Testing Technologies at The Battery Show 2024 as Part of Its Turnkey E-Mobility Solutions

July 3, 2024

- Comau’s commercially available cell formation and testing technologies now provide a European-sourced alternative for the battery production process

- The cutting-edge solution further underscores the company’s commitment to making large-scale, sustainable, cost-effective and locally available battery manufacturing solutions a reality

- Comau’s proprietary and dedicated solutions cover all phases of the battery module and pack production cycle and dismantling

- The cleanroom classified Racer-5 SENSITIVE ENVIRONMENTS high- speed robot is designed for low contamination battery and cell assembly settings

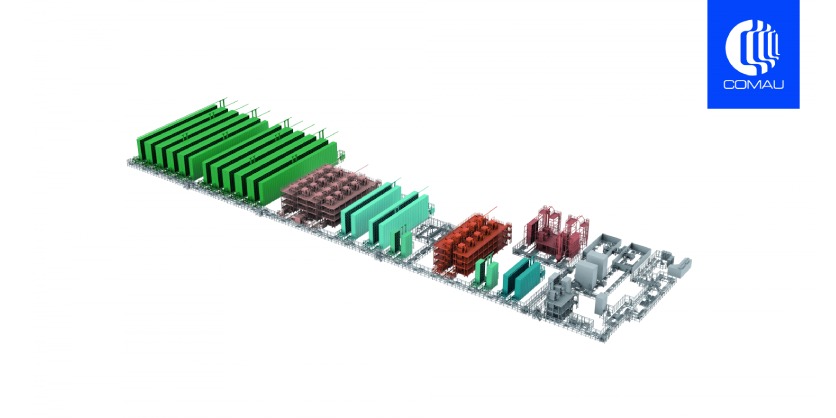

Comau showcased its advanced, turn-key battery cell formation and testing technologies at The Battery Show Europe conference, booth number 9-F50, held 18-20 June. In bringing its highly efficient and scalable battery cell formation solutions to the commercial market, the global automation company is among the first European players to locally source this key aspect of the battery manufacturing process. And because Comau can support its customers at all stages of the process – from lab-based prototypes to giga-scale production – it is in a perfect position to help enhance productivity, reduce costs, and prioritize safety and sustainability.

As a pioneer in advanced battery production technologies, Comau offers a vast range of solutions that fully support different stages of the production process. During the 3-day congress and battery technology show, which took place in Stuttgart, Germany, Comau also presented its latest developments in automated manufacturing systems for battery cells, modules and complete packs (with any cell format). Indeed, its 360° portfolio of products, processes and technologies allow Comau to handle everything from prototyping and pre-production to mass manufacturing and even end-of-life battery recycling. This ensures that manufacturers can seamlessly transition from development stages to mass production without compromising quality or efficiency.

Comau’s proprietary cell formation offer encompasses the core processes that transform assembled cells into stable, electrically charged battery. A crucial phase in the battery manufacturing process, it involves a series of charging and discharging cycles that ultimately ensure both optimal performance and longevity of the cells.

Comau’s cleanroom classified, high-speed Racer-5 SENSITIVE ENVIRONMENTS (Racer-5 SE) industrial robot will also be on display. Designed to easily automate applications with stringent requirements while reducing overall operating costs, the 6-axis articulated robot is ideal for battery cell assembly and the cleanroom assembly of microelectronics. In cell production, as in other parts of the battery production process, there are significant amounts of data to be collected and analyzed in order to control process and product quality. To address this, the company’s data management tools, among which Comau’s in.Grid platform, will be featured in the booth.

In addition to the innovative solutions already deployed at customer sites around the world, Comau continues to invest heavily in research and development for the industrialization of next generation technologies, among which solid-state batteries, hydrogen fuel cells, battery module and pack assembly, and battery trays processing.

Comau is also part of multiple pan-European e-Mobility projects. For example, the company is helping develop a more compact cell formation chamber layout and warehouse management strategy by optimizing the recuperation and reuse of electric energy and heat. Comau has also contributed to the development of a robotic system for the automated dismantling of used batteries. The system utilizes a flexible, repeatable and standardizable process that allows companies to reduce waste and optimize the reuse of materials that make up the battery packs. Similarly, Comau’s dedicated and highly specialized laboratories and battery innovation centers allow customers to test next- generation battery solutions and receive direct support for the definition and optimization of their processes.

“Battery demand is estimated to increase significantly between now and 2030, driven largely by the pan-European goal of creating an autonomous supply chain. Despite recent uncertainty regarding the growth rate, the battery market is still expected to exceed 170 billion Euros in 2030* and our broad ranging competence and versatile skills set allow us to respond to evolving scenarios.” explained Pietro Gorlier, Comau CEO. “Comau’s commitment to delivering best-in-class technologies, such as our new cell formation solutions, underscores our ongoing dedication to helping drive the world’s energy transformation goals. Leveraging our unique know-how, long-standing experience in automotive and strong global team, we will continue to support our growing client base and navigate their increasingly complex projects.”

Comau also unveiled its proprietary cell formation and testing solutions at booth number 9- F50.

*Comau’s internal estimates – including battery cells, modules, packs and e-motors – are corroborated by various market studies.

More Information

Related Story

Comau Presents Its New S-Family of Small, Fast and Element-Resistant “Hollow Wrist” Industrial Robots

Comau debuted its new S-Family of small yet powerful robots at Automate 2024, North America’s leading automation show. The first two high-speed robots, with payloads of 13 kg and up to 18 kg, are expressly indicated for assembly, arc welding and handling applications where accuracy, repeatability and speed are non-negotiable. Characterized by their exacting performance and historical red robot design, they also reflect Comau’s dedication to making automation more accessible to diverse and non-automotive industries.