Edgecom Energy Leverages Generative AI to Customize Energy Efficiency in Industrial Facilities

June 25, 2024

By Krystie Johnston

ABB recognizes Edgecom Energy’s innovative Energy Manager which leverages Generative AI to make better, informed decisions about energy consumption by awarding them winners of their 2024 Startup Challenge

Edgecom Energy is a Canadian startup that is using generative artificial intelligence (GenAI) to offer integrated energy management software programs that help industrial facilities use their energy more efficiently, thereby reducing costs and greenhouse gas (GHG) emissions. Behdad Bahrami, CEO and co-founder of Edgecom Energy discusses their platform and their recent success with the ABB Startup Challenge.

Behdad was inspired early-on in his career by sustainability and has a natural entrepreneurial spirit. After graduating from Materials Engineering, he worked as an Optimization Engineer for a machinery manufacturer to make their devices more efficient. His ability to improve the efficiency of these devices was quickly recognized, and he was offered an opportunity to apply his talents to an entire facility as an Energy Manager.

“This was in 2011, kind of like the early days of energy management. That job really aligned with my personal interests and my passion for sustainability. I started to see that there was a lot of potential in this world of energy for industrial facilities. There is a lot of money they can save, and a lot of emissions they can reduce. And that this is making a huge impact on their business as well,” says Behdad.

At the forefront of energy management, Behdad could see that there were ways for this facility to use energy more efficiently by being resourceful. And this approach could save the company money as well. He was able to save them almost $1,000,000 just by changing when they consumed energy. The company’s achievement became a beacon for other manufacturing facilities in Ontario. Behdad recalls that the Premier of Ontario and various politicians visited the plant and toured it to see firsthand how it had achieved these energy savings without affecting profitability.

A beacon for manufacturing facilities to save energy and money

Behdad saw the tremendous potential as well, and started to wonder how he could help more facilities manage their energy more efficiently as well. He decided to try and make that impact. “I launched Edgecom Energy in 2016 and started consulting for other facilities. And I realized that this consulting work was not going to make the impact I envisioned. How many facilities can one person really do the consulting for? There is a lot of data, and a lot of work to be done. How can this be made more scalable? And I realized that it has to be with software,” he recalls.

In 2018, Behdad attended an energy conference where he encountered ideas he had been contemplating, echoed by Dr. Ashkan Rahimi-Kian, a professor of electrical engineering with a PhD. Dr. Rahimi-Kian emphasized that the future of energy lies in data, AI, and machine learning. This resonated with Behdad, sparking his interest and prompting him to attempt to recruit Dr. Rahimi-Kian to join Edgecom as it pivoted towards software development.

Through the professor, he was introduced to Mehdi Parvizi who was completing his PhD in Power and Energy Systems at the University of Waterloo and was also working on Machine Learning image processing algorithms as his side-job while in school. Parvizi joined Behdad and eventually became CTO and Co-Founder of Edgecom Energy. Together, they worked on developing software that could serve as an Energy Manager for any industrial facility, and in 2018 they launched their first version of their platform.

Edgecom creates an Energy Manager for every industrial facility

“The goal for Edgecom is to give every industrial facility an Energy Manager. But that is not going to be a person, it is going to be software and AI. I was that Energy Manager. Now I want to give that Energy Manager to every facility in the world, and we are taking steps towards that goal every day,” says Behdad. Having an Energy Manager is crucial for companies to gain a comprehensive understanding of energy costs and to make informed decisions that optimize energy consumption, and software and AI are the keys to scaling this platform.

“At Edgecom Energy, our core products have been machine learning and machine learning models. Our core business is predicting energy prices and energy demand for these industrial facilities. We combine that with a lot of other capabilities that our software can do to create an optimal load schedule. At any facility, if you move not what you do but when you do it, there are significant savings that can be achieved. There is a lot of processing, data, and information. And a lot of that data changes in real time,” says Behdad.

Behdad says that AI is instrumental in being able to process this data in real time to provide an optimal load schedule. The team at Edgecom Energy have combined new large language models (LLMs) with traditional machine learning models (MLMs) to create a kind of translation tool that takes the queries of a plant manager tasked with optimizing energy efficiency and uses a vast pool of datasets to generate an optimal load schedule for a given plant.

Edgecom Energy continues to improve sustainability and energy efficiency

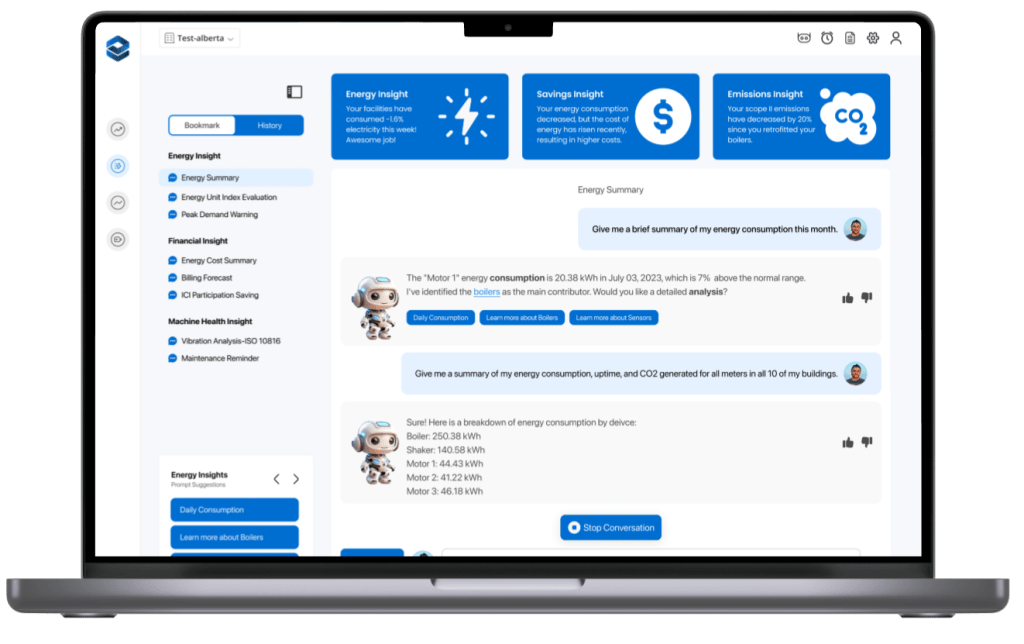

Edgecom Energy has developed a suite of Energy Management software that offers energy solutions for high energy consumers. They launched their AI Energy Copilot a year ago and it was a perfect fit for the ABB 2024 Challenge because it supports energy transition and a low carbon future. For Behdad, the challenge was aligned with his goals of bringing an Energy Manager to more industrial facilities and fit seamlessly with his passion for sustainability.

“ABB is a very well-respected company. We like a lot of the things they are doing on the hardware side, and we thought this would be a good opportunity for more facilities to get the CoPilot faster. The mission of Edgecom is to make an impact on how industrial facilities operate and make them more sustainable and cost effective. You look at what is the fastest way to reach more facilities and I thought ABB would be a massive opportunity,” says Behdad.

Winning the ABB Startup Challenge was like a stamp of approval for Edgecom’s AI CoPilot. For Behdad, it affirmed that their vision and offering are on the right track. “Their ideology behind the challenge matches with what we are trying to do, and we already have a lot of the pieces figured out. We have all these peak management products. We have all these software products, and then we built this CoPilot on top of it to make it easier for customers,” says Behdad.

Edgecom Energy’s partnership with ABB will enable them to optimize their product even further and help them reach more industrial facilities. Behdad sees a lot of growth potential for energy transition and is excited about the impact that putting an energy manager into the hands of more industrial facilities will have on supporting a low-carbon future.

More Information

Related Story

ABB Startup Challenge Winners Use AI to support the Energy Transition

Some of the most innovative startups were recognized at this year’s ABB Startup Challenge in the Sophia Antipolis technology park near Nice, France. The competition invited startups to explore how AI could be incorporated into existing energy industry platforms and systems supporting the energy transition and a low-carbon future.