ANCA’s ToolRoom Update 137.00 Introduces Enhanced DCREM Tools with Cost and Time Saving Benefits

May 29, 2024

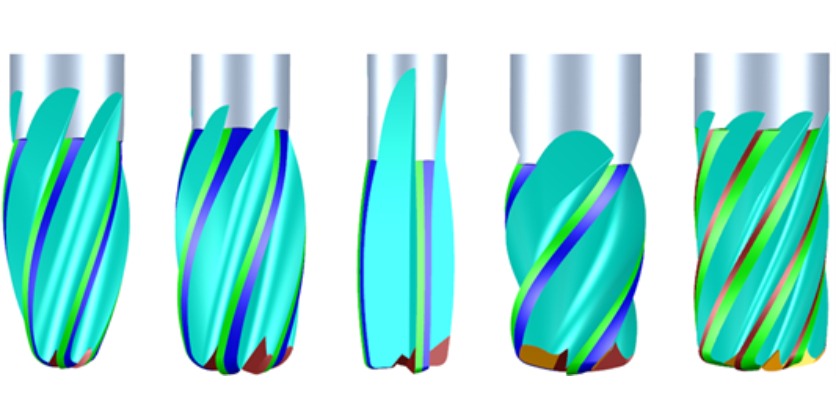

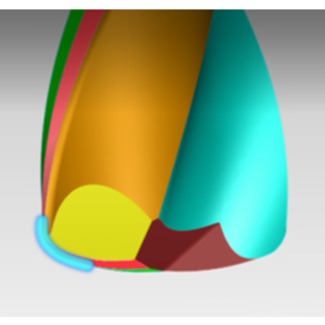

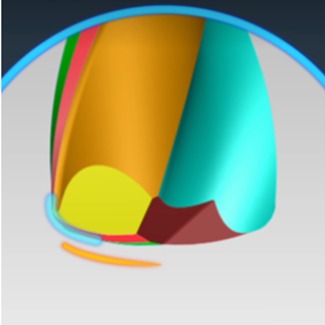

In ANCA’s latest ToolRoom update, version 137.00, the introduction of Lens and Barrel-shaped double corner radius tools (DCREM) marks a significant enhancement to the existing DCREM offering. This update allows customers to manufacture complex, high-performance endmills while enjoying substantial cost and time savings. Commonly referred to as circular segment cutters or high feed endmills in the market, these tools find extensive application across diverse industries such as die mould, aerospace, general machining, and power generation.

DCREM cutters excel in producing critical components like tire moulds, turbine blades, impeller blades, or Blisks, serving as an alternative to conventional corner radius tools. The measurement methods, including iView and LaserUltra, ensure precision and efficiency in the manufacturing process. The inclusion of DCREM tools complements ANCA’s existing BSB (Barrel Shape Ballnose) ToolTypes, providing a comprehensive solution for circular segment cutter needs.

ToolRoom RN34.1 update 137.00 includes several enhancements as shown below.

- Ability to offset the centre of the lens radius from the centreline of the tool.

- Addition of dish angle to the centre instead of the radius all the way to centre (Currently we can only do radius to the centre and have no option to have a line dish).

- The dish has an option to be tangential to the lens arc with and without a radius

- Parameter is available to specify the start of the dish section from the end of lens radius

- Supports dished, lens and dished lens Endface types

- Body has support for Barrel, straight and taper

- Barrel definition includes Neck diameter, form diameter and form taper

- 4 radii options including fillet

Benefits

- The geometry of these Endmills are the large radii in the cutting area of the respective tool which offer entirely new possibilities in machining.

- The larger-radius edge permits larger stepover increments which enables machining with a larger cross over pitch or tool path distance during pre-finishing and finishing operations.

- The large tangential form radius simulates a Ballnose or Corner Radius Endmill with a large cutting diameter, saving cycle time relative to a Ballnose or Corner Radius tool.

- Not only does productivity improve, the resulting surface finish is better as well.

Advantages of ToolRoom

- iView and LaserUltra compensation for large volume manufacturing

- Variable helix/index with radial margin in fluting for easy setup

- Tool balancing for variable helix/index tools for chatter free cutting

- User-friendly wizard-based design specially for catalogue tools

- Complete tool runout compensation option

- Support for chip breakers

Related Story

ANCA Expands its Global Footprint Opening a New Technology Center in Korea

ANCA, a leading innovator in precision grinding solutions, is thrilled to announce the grand opening of its new state-of-the-art Technology Center in Korea. ANCA has offered local sales and service to customers across diverse industries for more than 30 years in the Korean market and opening the new facility is a significant milestone for the company as it expands its presence in the Asian market.