Siemens Xcelerator: Siemens and AWS Simplify IT/OT Convergence with An Integrated Edge-To-Cloud Experience

November 30, 2023

- AWS IoT SiteWise Edge now available as application on Siemens Industrial Edge Marketplace

- Seamless integration of edge and cloud helps customers optimize industrial operations

- Collect, organize, and analyze Industrial Internet of Things (IIoT) data at scale to make better, data-driven decisions

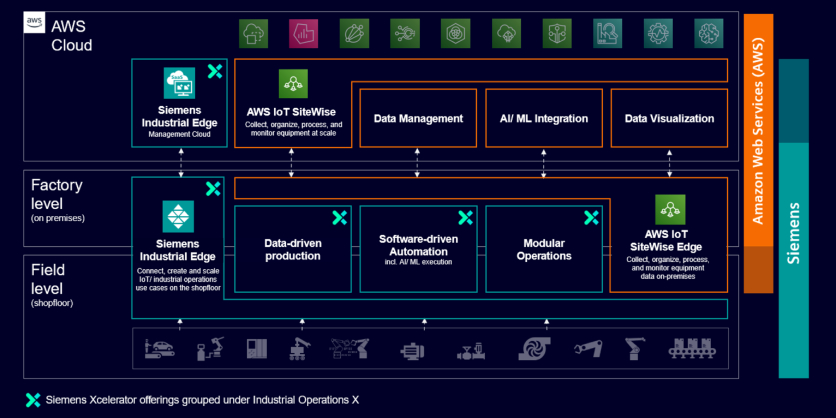

AWS IoT SiteWise Edge is now available on the Siemens Industrial Edge Marketplace. From there, customers can deploy it on Siemens Industrial Edge for centralized app and device management and combine it with a variety of other apps and edge devices, from Siemens and other vendors, to configure an IoT solution for their specific challenges. AWS IoT SiteWise Edge is an on-premises software that is part of the Industrial IoT services portfolio of Amazon Web Services Inc. (AWS) and can collect, process, and monitor equipment data locally, even without an internet connection.

Siemens launched its open Industrial Edge platform in 2018, and expanded it in October 2021 with the Industrial Edge Marketplace, an independent, cross-vendor app store where industrial customers can buy apps from different IoT providers. The Industrial Edge platform and Marketplace are part of Siemens Xcelerator, an open digital business platform, which creates an open ecosystem for collaboration between customers, Siemens, and complementary third parties. And as such they are also part of Industrial Operations X, an open and interoperable portfolio for automating and operating industrial production.

“The addition of AWS IoT SiteWise Edge to our Industrial Edge Marketplace creates new opportunities to deploy edge and cloud applications at scale and manage closed-loop automation workflows“, says Rainer Brehm, CEO of Factory Automation at Siemens. “Our customers are constantly facing new challenges to boost productivity, flexibility, and sustainability across their production processes. To help them, Siemens is expanding its traditional strong OT portfolio by integrating IT and software capabilities into automation with Industrial Operations X.” With Industrial Operations X, Siemens provides its customers also with an integrated portfolio of operations software combined with an open ecosystem.

Rainer Brehm, CEO of Factory Automation at Siemens

Leveraging edge and cloud to simplify IT / OT integration

With AWS IoT SiteWise Edge on Industrial Edge, AWS and Siemens will accelerate and simplify the machine-to-edge and edge-to-cloud experience. Customers need less time to start ingesting data into the AWS cloud and use further AWS services, e.g., for simplified data and workflow management or Industrial artificial intelligence (AI) workflows on the edge and the cloud. Today, the majority (74%) of customer IoT projects remain isolated experiments (Source: Beecham Research “Why IoT projects fail”), require a long period of time to deploy at scale or do not achieve the expected return on investment (ROI) due to a heterogeneous landscape of OT (Operational Technology) and IT systems.

This results in data being difficult to access and use, as it is often restricted to a single machine or shop floor. Customers can now start to unlock the value of industrial data by processing it in workflows which today they must choose to run either on the edge or in the cloud. AWS IoT SiteWise Edge on Siemens Industrial Edge helps build a secure, flexible edge-to-cloud infrastructure that can deliver data where it is needed and run hybrid workflows, simplifying IT / OT convergence.

Rapid development, scalability, and repeatability of IIoT use-cases

Customers using AWS IoT SiteWise Edge and Siemens Industrial Edge benefit from a wide range of industrial connectivity options, data storage and management, security capabilities, and analytics and visualization technologies across the edge and the cloud. With this offering, automation engineers, maintenance technicians, and operations managers can decide what data needs to be collected and where it is stored, processed, or analyzed. With Industrial Edge, the IoT solution development and deployment becomes easy, secure, and scalable.

Extracting value from industrial IoT data to optimize industrial operations

With AWS IoT SiteWise Edge, businesses can increase production efficiencies, improve manufacturing operations by monitoring performance metrics, and optimize asset maintenance through remote asset monitoring using historical and real-time data.

The Siemens Industrial Edge Ecosystem is growing, with more and more edge apps and devices being available on the Siemens Industrial Edge Marketplace. With today’s announcement, Siemens and AWS bring the power of industrial automation (OT) and the cloud (IT) together to offer a streamlined machine-to-edge and edge-to-cloud experience to manufacturing customers.

More Information

To access the Siemens Industrial Edge Marketplace, please click here.

For AWS IoT SiteWise Edge on the Marketplace please click here.

Further information on Siemens Industrial Edge is available here.

Related Story

Siemens To Invest More Than US$500 Million In U.S. Manufacturing for Critical Infrastructure In 2023

Siemens has announced an investment of US$150 million in a new high-tech manufacturing plant in Dallas-Fort Worth to help power American data centers and critical infrastructure. This plant will produce state-of-the-art reliable and efficient electrical equipment. It will enable accelerated growth of U.S. data centers, which is being driven by the exponential adoption of generative AI. It will also ensure secure operation of critical infrastructure. This investment specifically supports long-term customers in the data center space, where demand is expected to grow by around ten percent annually through 2030.