Shaping Innovation: Comau Launches Sustainable Advanced Automation Solutions at Automatica 2023

August 22, 2023

- Comau, having just celebrated its 50th anniversary, is shaping innovation with sustainable, advanced automation solutions that respond to the rapidly growing worldwide market within and beyond traditional Automotive sectors

- MATE-XB: A wearable exoskeleton for the lower back to support workers during bending and lifting activities

- Hyperflex: A revolutionary mobile factory to increase the efficiency of solar panel installation

- An easy-to-use mobile robot that can autonomously weld steel to achieve both higher productivity and higher quality

- Intrinsic Flowstate: An intuitive web-based developer tool for solution builders designed to make robot programming easier for experts and non-experts alike, including industries approaching automation for the first time. Comau is Intrinsic’s longest standing innovation partner.

- MI.RA/Picker: A fully automated, high-speed bin picking system that autonomously recognizes, locates and grasps randomly placed objects

- Solutions for e-mobility: battery assembly, dismantling and recycling, and more

Comau is shaping innovation and taking digital-driven, advanced automation to a whole new level with powerful new solutions designed to accelerate deployment, increase quality and ensure sustainable productivity inside and beyond the smart factory paradigm.

From June 27-30 in Munich (Germany), Comau, which recently celebrated its 50th anniversary, unveiled its advanced solutions to increase the efficiency of solar panel installation, a new wearable exoskeleton capable of assisting the lower body during bending, lifting and repetitive tasks, and a mobile robotics solution for unstructured environments to achieve both higher productivity and quality – all of which made a worldwide debut at Automatica 2023 (Booth B4 – 109). Comau’s unique approach is making advanced automation increasingly simple, intuitive and accessible.

Accompanied by a steadfast commitment to sustainability and a full portfolio of enabling products, technologies and digital solutions, the company is able to meet increasingly variable production requirements in non-static environments.

Automatica was also the perfect place to launch Comau’s new wearable exoskeleton, developed with IUVO, and in collaboration with Esselunga, both as an early adopter and a validation and testing partner. The new lumbar exoskeleton is capable of assisting the lower body during bending, lifting and repetitive tasks. Lightweight, highly breathable and able to withstand extreme outdoor elements including corrosive marine environments, MATE-XB further confirms Comau’s commitment to wearable robotics, as the company now covers both upper and lower body support needs.

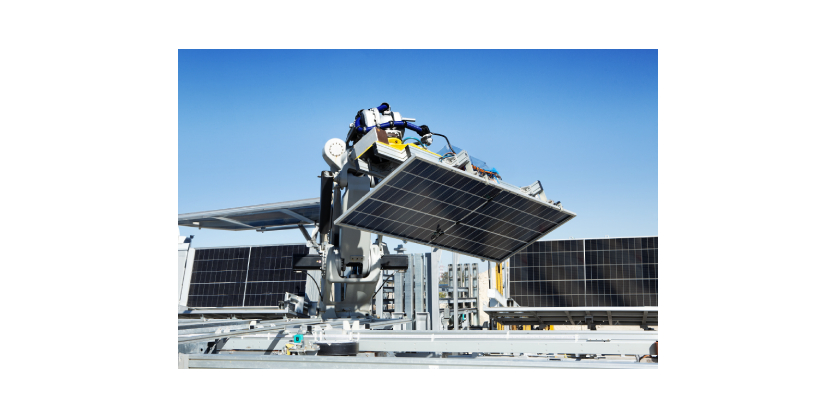

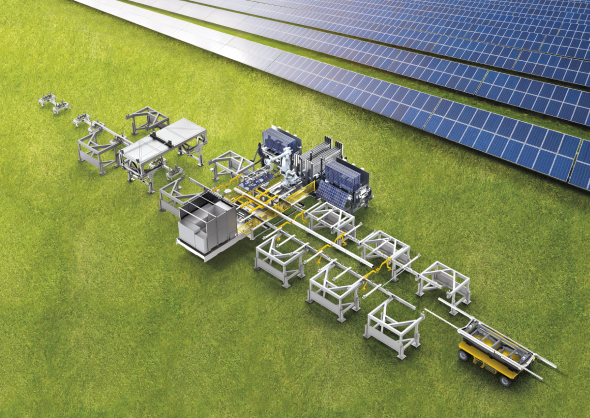

To increase the on-site installation of solar panels at new and existing photovoltaic plants, Comau unveiled its Hyperflex mobile outdoor factory. Representing a new paradigm in automation, the patented, robotized solution directly assembles tracker components in the photovoltaic field, helping facilitate green energy production while improving process quality, overall productivity and operator working conditions.

In addition, Comau showed how it is shaping innovation with an unprecedented autonomous mobile welding system. Considered a new paradigm in bringing automation to an unstructured environment, it was co-developed with an important partner and can be used for various applications in multiple industries. Indeed, the two companies will unveil the cutting edge mobile robotic solution at a dedicated press event scheduled June 28 at Automatica.

The company also demonstrated how Intrinsic Flowstate, a web-based developer tool for robotic solutions development, is accelerating automation by making robots moreintelligent, easier to program and readily accessible to any industry. Comau is a longstanding innovation partner of Intrinsic and has helped to scope, test and validate Flowstate. The implementation and integration of Intrinsic’s advanced software capabilities will enable Comau to easily develop scalable, cost-effective solutions and preconfigured application templates that can be used to quickly deploy new or modified solutions.

Comau’s customers benefit from capabilities such as object pose estimation, automatic path planning with collision avoidance, controlled moves until contact, peg-in-hole applications and force-sensing assemblies. The software platform from Intrinsic will help drive robotics adoption and cost-effectiveness by helping companies in many industries access modern automation that can be easily deployed.

Furthermore, the collaboration between Intrinsic and Comau was showcaseded in Intrinsic’s booth (Booth B4 – 310, next to Comau’s booth) with a dedicated assembly station and Comau robots used for applications with real-time, sensor-based control. The first demo demonstrated how Intrinsic Flowstate was used to design and program a solution for the assembly of rigid components – using an AI-based vision system, forcecontrolled insertion and robotic path planning with collision avoidance. The second demo used a Comau Racer-7 robot able to switch online smoothly from a force-torque sensor to a laser range finder to follow an irregular surface.

Comau’s advanced automation solutions are being applied to very complex and nonlinear processes in an open and intuitive way by leveraging enhanced vision systems, sensors, neural networks and its powerful robot control interface. Two concrete examples, on display at Automatica for the first time, was the MI.RA/Picker and MI.RA/Depalletizer solutions, which have been designed to automate product sorting, receiving, and picking operations that are typically performed manually due to the high variability of parts and products. By automatically detecting and distinguishing between items, the advanced industrial robotic systems allow companies to streamline their processes, improve their flexibility and minimize production losses.

Connected to MI.RA/Depalletizer, it will also feature Comau in.Grid, a proprietary IoT solution for data collection and line/cell//product/process monitoring.

Finally, the company presented its vast e-Mobility offering, which includes automating manual processes and application areas that have been largely inaccessible with traditional robotic technologies, including cell formation, battery dismantling and battery repurposing processes.

Similarly, Comau displayed a highly effective robotic welding training solution based on its e.DO™ educational robot and Seabery Soldamatic technology. The innovative simulated learning module is a direct response to the prohibitive characteristics of traditional welding training, which is costly, time-consuming and requires dedicated safety equipment. By providing a multi-sensory interface that includes sight, sound and touch, the highly calibrated and parameterized system creates the most realistic welding training experience aside from actual welding.

“Demand for automation is growing by more than 10 percent annually, with even higher peaks in new sectors that have had little to no automation until now,” explained Pietro Gorlier, Comau CEO. “Comau is shaping innovation by consolidating its long standing expertise and working with a strong network of global leaders in their fields to develop increasingly diversified technologies, based on advanced robotics and digitalization, that can make production processes in many sectors increasingly efficient and sustainable. All this is possible thanks to our commitment to advanced automation and the skills of our people who, for the last 50 years, have been adding value to our company.”

Pietro Gorlier, Comau CEO

Related Product

Comau Unveils “MI.RA/PICKER”, A Fully Automated Perception-Based Random Bin Picking Solution

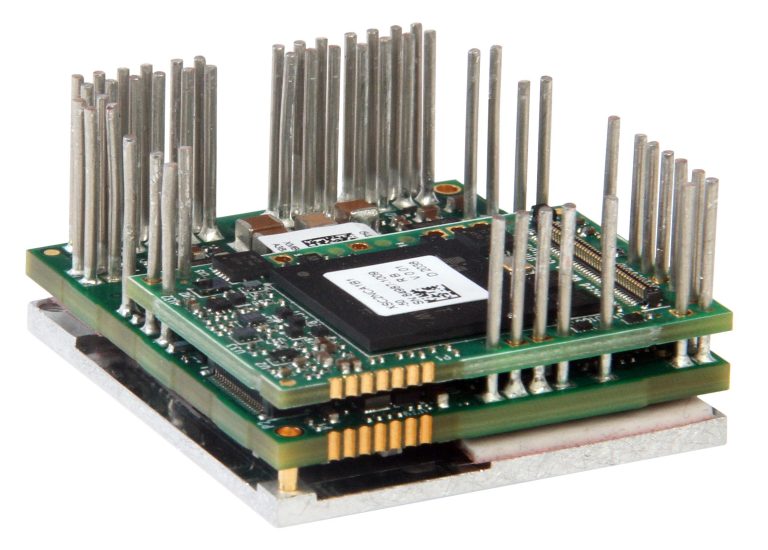

Comau introduces “MI.RA/PICKER”, an intelligent advanced automation solution for perception-based random bin picking. Adaptable to any brand of commercial robot, customized bin or customized gripper, the fully automated picking solution uses two high-resolution laser sensors and a central camera to autonomously recognize, locate and grasp randomly placed objects at a rate of up to 40 pieces per minute (PPM).