Leuze Sets New Standard for Compact Positioning System

April 10, 2023

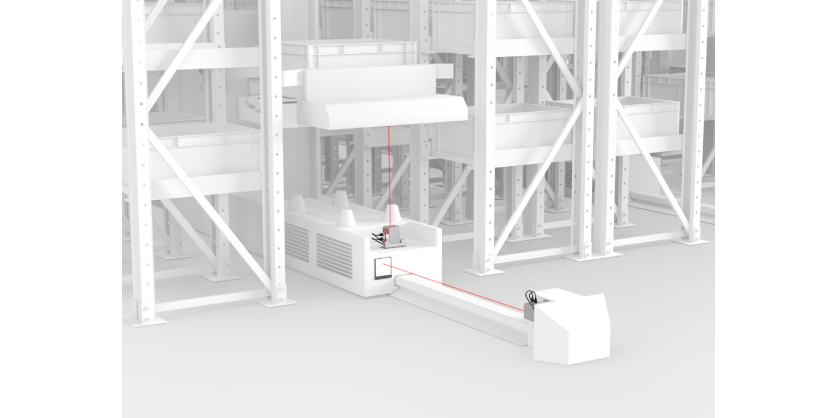

The AMS 100i from Leuze is one of the smallest laser positioning systems available on the market. This makes it the perfect solution for tight installations spaces.

Whether on the stacker crane, automated guided vehicle, or lifting system: In automated intralogistics, the sensors used for positioning applications must be able to operate on a small footprint in many cases. The new AMS 100i from Leuze is up to the task without sacrificing performance. With its small dimensions of 105 x 68 X 75 mm, it is one of the most compact laser positioning systems on the market. This makes it the perfect solution for use in tight spaces. The sensor works with very high accuracy: With the AMS 100i, users are able to position with millimeter accuracy for up to 120 meters.

Positioning right up to the sensor

The Sensor People have developed the AMS 100i with a minimum blind zone of only 100 mm. This enables positioning applications right up to the sensor. The available space is used efficiently. Useful: Modular assembly options and easy alignment facilitate flexible and quick installation.

Reliable in heat and icy cold

The modular laser positioning system is also available in the AMS 300i version. This device model offers an operating range of up to 300 meters. Both variants meet the high requirements of degree of protection IP65. Optionally, the AMS 100i and the AMS 300i are also available with integrated device and window heating. With this variant, the sensors can be used for low-temperature applications down to -30°C (without heating down to -5°C). In hot ambient conditions, the AMS 100i is designed for temperatures of up to +60°C.

More Information

Related Product

Gapless Safety from Leuze

In applications where corridor supply vehicles interact at transfer stations with a direct connection to a danger zone, operation must be as safe and efficient as possible: Throughout the entire area, the safety system must be able to differentiate reliably between forklift trucks and, in some cases, also people. This is possible using a Leuze safety solution for multi-station access guarding in forklift truck logistics.