u-Control – The Heart of Every Automation is the Control System

February 16, 2023

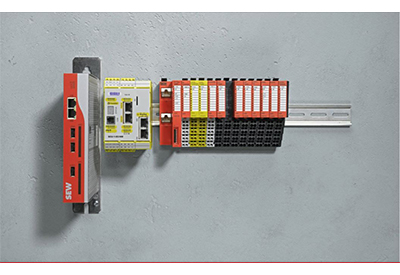

Thanks to the scalable engineering software, Weidmüller’s u-control 2000 adapts individually to your requirements. Furthermore, the u-control is powerful, compact and fully compatible with our I/O system u-remote.

Your benefits at a glance:

- Flexible: Based on the compact u-remote fieldbus coupler design, u-control 2000 can replace it on a one-to-one basis

- Space-Saving: Despite only 54 mm width

- Secure: The “Security by Design” concept provide you with top-notch security

Product range

u-control M3000 & M4000

Modular controls for industrial automation and IoT applications

In the course of automation, more and more physical devices are being integrated into networks. This is driving the trend towards convergence of IT and OT systems. The new modular u-control M3000 and M4000 control systems point the way to the future.

With u-control M3000, automation solutions can be perfectly integrated into the IoT. The powerful controller also works as an edge device for providing local information in the network and can be expanded by connecting function modules – ideal for automation and IIoT applications. u-control M4000 also offers two CPU cores, two Ethernet interfaces and more RAM, NVRAM, and flash memory for complex edge computing in automation.

- Optional expansion with additional interfaces (fieldbuses, Wifi, LTE)

- Simple option for coupling supplementary function modules

- MultiCore technology for independent installation of several runtime systems

- M3000 with two CPU cores & M4000, with 4 CPU cores

- High degree of freedom and flexibility in the selection of technologies

u-control 2000

For modern IoT applications, automation technology needs to be ever more powerful and adaptable.

u-control 2000 is one of the most compact and state-of-the-art control systems on the market and is the centrepiece of our hardware portfolio.

- Dual-core technology allows real-time applications to be separated from non-time-critical applications

- 512 Mbyte RAM, 4 GB flash memory and space for a micro SD card of up to 32 GB

- I/O Modules direct adaptable

- Approvals: ATEX, IECEx, DNV

Software & Engineering

Operating system u-OS

Independence and flexibility for your machines and facilities

u-create web

Flexible engineering in a web-based programming environment

Easy. Future-Proof. Cooperative.

With Weidmüller’s u-control we will support your automation. Your automation needs more technical Know-How? Visit Automation Solution and discover more about their complete automation portfolio.

More Information

Related Story

Single Pair Ethernet Promises a Consistent Ethernet Connection from the Sensor to the Cloud

Single Pair Ethernet (SPE) is the catchword when it comes to the network infrastructure for the Industrial Internet of Things (IIoT). Users hope it will allow them to implement a consistent communication architecture in all applications where data is present. This is based on the concept of extending Ethernet connection right down to sensor level, i.e. wherever there are no data highways but where users need compact data transmission with a long reach.

Industrial-Ethernet networking is used in industrial applications and offers a range of benefits thanks to its real-time transmission. However, the technology is too complex for simple sensor applications. “At the sensor level, we are still using bus architectures. We now want to create an IP-based communication infrastructure with a uniform communication protocol, reaching from the sensor to the cloud”, explains Simon Seereiner, Head of Product Management SAI & IE at Weidmüller.

Single Pair Ethernet makes it possible. After all, SPE does not require excessive data transmission rates and can span more considerable distances, while also having a more compact design. Unlike cabled Ethernet connections, this technology requires just one pair of wires rather than two or four pairs. This is down to development in the automotive sector, where space and weight savings are of utmost importance.