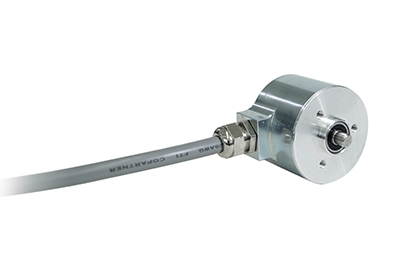

New VERO-S AFS3 IOL Sensor from SCHUNK Detects Three Clamping States

February 1, 2023

The versatile SCHUNK VERO-S modular system enables workpieces and clamping devices to be mounted, positioned and clamped in no time at all. With its new VERO-S AFS3 IOL monitoring sensor, reliable information is provided on the clamping states of the modules.

Uncertainty in automated clamping has been consigned to the past: the new VERO-S AFS3 IOL brings greater transparency to the clamping process, thereby ensuring precision.

The sensor will reliably monitor the clamping slide positions and whether the module is ‘open’, ‘clamped with clamping pin’ or ‘clamped without clamping pin’ via an IO-Link signal. An LED light indicates the clamping status, ensuring additional operating safety.

The component can be combined with SCHUNK clamping modules of the NSE3 138, NSE3 99 and NSE3 100-75 series. An inductive proximity sensor also indicates whether there is a pallet above the modules.

This smart electronic monitoring system interaction ensures greater safety in automated workpiece clamping for users. This guarantees a consistently high level of process reliability. There is no need for pneumatic clamping slide monitoring.

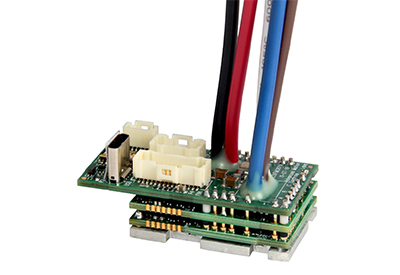

As well as convenient indication of clamping status, the simple programming is another customer benefit – teaching of the VERO-S AFS3 IOL is via the standardized IO-Link interface and is completed in no time at all.

A wide range of process data can also be recorded via this interface. The VERO-S AFS3 IOL operates with an energy-saving nominal voltage of 24 volts. It is very easy to install and is mounted outside the clamping module support.

More Information

Related Product

SCHUNK’s New High-Performance Universal Gripper

With the new optimized 2-finger parallel gripper JGP-P, SCHUNK is further expanding its family of universal grippers alongside the SCHUNK flagship PGN-plus-P. The successor of the JGP has the advantage through its increased gripping force, flexibility in application, and a variety of query options. With this development, the gripping system specialist continues to raise the bar when it comes to price/performance optimized pneumatic grippers.