POSITAL LINARIX Sensors: Rugged Linear Position Sensors with Optimized Accuracy

September 22, 2022

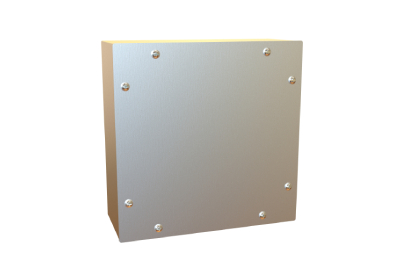

POSITAL LINARIX linear positions sensors have been updated with extra-heavy-duty draw-wire mechanisms and with a convenient pre-scaling option for devices with analog communications interfaces. LINARIX position sensors are ideal for a wide variety of applications, including medical equipment, packaging and materials handling systems, forklifts, overhead gantries, lifts, and flow control gates in water management systems.

LINARIX sensors combine a multi-turn absolute rotary encoder with a robust draw-wire mechanism. As the wire is drawn off the device’s spool, the encoder measures shaft rotation and reports the result to the control system. These devices are both accurate and durable, with draw-wire mechanisms that are rated for over one million cycles. Furthermore, the rotary encoders are based on non-contacting magnetic measurement technologies that are immune to the wear or corrosion that can degrade the accuracy of potentiometer-based draw-wire devices. Analog, DeviceNet, CANopen and SSI output interfaces are available.

LINARIX sensors with analog output are programmed in the factory so that the output range (e.g., 0 – 10 V, 4 – 20 mA) spans the full measurement range of the draw wire mechanism. Customers also have the option of specifying the measurement range required by their application. In this case, the sensors will be pre-programmed at the factory so that the output range exactly matches the range of distances that the device will encounter when it is in service. This will simplify setup, improve the accuracy of analog control systems, and make it easier to install LINARIX sensors as drop-in replacements for older linear sensors, such as string pots.

Users can also set the measurement range for their analog LINARIX sensors in the field with POSITAL’s convenient UBIFAST programming tool, making it easy to fine-tune the instruments or update them to accommodate modifications to the machines where they are installed.

New ultra-heavy-duty versions are available with environmental protection ratings up to IP69k. These are designed to stand up to high-pressure water jets from pressure washers making them a great choice for concrete-placing boom trucks and other construction equipment. Special models will be available with a built-in tilt sensor (inclinometer) to track both boom angle and extension from a single device.

Finding the right LINARIX sensor for a particular application is straightforward. The web site www.postial.com provides a powerful product finder tool that enables a customer to select the product features required for each application, then zero in on the appropriate product.

To learn more about LINARIX sensors, click here