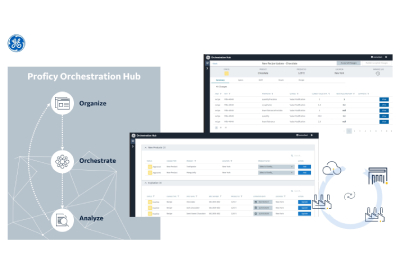

GE’s New Proficy Orchestration Hub is Industry-First Solution to Unify Manufacturing Product Data Management Across the Enterprise

February 16, 2022

GE Digital recently announced its newest addition to the Proficy Software portfolio, Proficy Orchestration Hub. This new software solution provides out-of-the-box tools to unify manufacturing product information from disparate data systems, transforms and organizes raw business-oriented information into production-ready formats, and orchestrates the information across factory floor systems at a single site or multiple sites.

Proficy Orchestration Hub allows manufacturers to stay in sync with constant updates to manufacturing product data to provide higher quality and throughput. It can enable faster time to market with accurate product data based on unified information mapping data from different systems such as Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM) into Manufacturing Execution Systems (MES).

Accurate product manufacturing data, that is readily available during production execution, decreases waste by about 10% per plant annually from less rework and rejects. It also reduces production delays and compliance issues, leading to approximately 5% improvement in on-time delivery and 1% decrease in compliance-related costs.

“We collaborated with GE Digital on the development of this solution to support improved accuracy and efficiency in identifying and implementing specification changes,” said Kevin Briggs, Architect, IS Operations for The J.M. Smucker Company. “By integrating systems and digitizing operational product data management, we can create greater flexibility in manufacturing environments, reduce waste and costs, ensure consistent quality and compliance and increase production throughput.”

With supply chain issues, more products and/or regulatory standards, production can get out of sync with the latest manufacturing product data, resulting in lower quality, increased waste, and operations headaches. Proficy Orchestration Hub records and allows users to analyze the updates to manufacturing product data at a given plant. It also stores deviations and comments, recorded as variances, to provide visibility into a plant’s adoption of the changes. This allows manufacturers to decrease quality variability due to ad-hoc modifications as well as the non-productive time and manual efforts trying to execute standard production work.

“With most manufacturers at various points in their digital transformation and IT/OT convergence journey, there remains a void to be filled in their ISA-95 data models between the level four enterprise systems, such as PLM, supply chain management, and ERP, and the level three production systems, such as HMI/SCADA, historians, and MES,” according to Craig Resnick, Vice President, ARC Advisory Group. “GE Digital’s Proficy Orchestration Hub fills this void by providing production optimization applications, such as manufacturing product data management that offer a unified, contextualized view of product data and enable seamless connectivity between the applications, truly creating level 3.5 and acting as a critical IT/OT convergence enabler and digital transformation accelerator.”

Companies have been struggling with various manufacturing product data orchestration issues such as spreadsheets with tens of tabs and thousands of rows, paper records that can be inconsistent and overwhelming, and multiple recipe changes that have to be coordinated across production lines. The “new normal” with its supply chain issues has acerbated these traditional challenges as companies are forced to modify recipes to work around shortages.

“Proficy Orchestration Hub helps manufacturers solve common challenges such as inefficiencies in production due to inaccurate product data, siloed and custom approaches to product data, compliance risks, and lack of quality standardization,” said Richard Kenedi, General Manager of GE Digital’s Manufacturing and Digital Plant business. “For companies that are tired of cobbling together plant systems or manually trying to capture the right product manufacturing data on paper, this solution can help increase throughput, reduce waste, and improve quality with manufacturing product data management at their fingertips.”

For rmore information about the Proficy Orchestration Hub, click here

To learn more about GE Digital’s Manufacturing Software suite, click here