Festo’s Seamless Connectivity Part 2 – Communication Protocols

December 15, 2021

By Krystie Johnston

These days, different standards are emerging at various levels of automation: products, communication protocols, safety standards, etc. Festo’s Automation Platform provides to the industry an adaptable, flexible, and convenient solution to gather huge amounts of different field devices, from servo drives to inductive sensors, by providing standards and protocols suitable for major PLC brands, allowing an easy integration and data gathering, ready for Industry 4.0. Presented at the German Technology Day 2021.

In part 1 of this article, the latest electrical automation products by Festo were discussed with respect to how they play a role in seamless connectivity. The other aspect of this concept is the communication protocols that these components use to make a connection between user and equipment. Festo has developed several interactive tools to make the selection of electrical automation easier and more seamless for their customers.

Seamless connectivity begins the moment that a customer interacts with Festo’s website using their online sizing and engineering tools. These tools not only help customers select the right components, but also help them to visualize their own concept. Earlier this year Festo introduced their newest electric motion sizing tool or EMS. This tool replaced a more cumbersome program requiring customers to load it on their computer and manually enter parameters and transfer files back and forth until an ideal setup was achieved. Festo is moving toward EMS, which is now online on their website, allowing the company and customers to collaborate and interact with each other. As Business Development Manager David Dolezal explains, “We can share, we can talk about things virtually, in virtual space. As this product gets developed it will have more and more components added to it, but it’s definitely a starting point.”

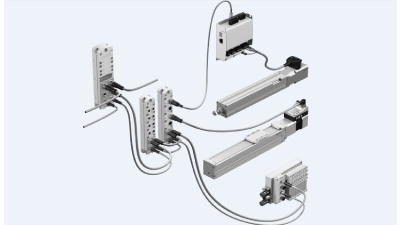

Festo’s handling guide online or HGO is another tool that allows users to design their own multi-access gantry systems in minutes. HGO is an online wizard on Festo’s website that guides customers through the requirements needed to accurately size and select the components for a new turn-key single or multi-access gantry system. Cable track, motors, actuators, controllers, and more are all selectable, the only thing the customer needs to do is enter their data. The customer gets a unique C number for the project, three-dimensional data, CAD data, and pricing. “You can actually log yourself in online, start an account, and within 10 minutes, build a full, multi-access gantry system with CAD data and pricing.”

Configuration is the next step once all components have been sized, selected, and purchased. These virtual components can be imported into Festo’s automation suite software. The software recognizes mechanical limits and sets servo drive parameters accordingly to avoid damaging vital components with over-torquing or over-positioning limits. This could help reduce human error. Programming can be daunting to many; however, Festo’s automation suite can simplify the process by connecting customers to an in-house support team. “We are not just a brown box vendor; we really are an automation partner. If you require function blocks, within the code assist libraries, if you require add-on instructions for your third-party PLC, we’re really able to help you connect all those dots.”

Working towards the goal of seamless connectivity by improving on these major touch points and making it easier to find and use Festo’s tools on their website will give customers more confidence. Festo continues to develop functions to import configuration data into real-world devices, reduce time configuring server drives, setting parameters, and ultimately, makes the transition from commissioning to programming faster and easier.

Festo has also invested a lot of time and resources to maintain a high level of programming and application support, including the development of function blocks, add-on instructions for third-party POCs, and control manufacturers, so that someone is available to support customers when and how they need it. “The concept of seamless connectivity isn’t only to connect and communicate within Festo, it’s a continuous journey with all of our automation partners. As the requirements for FIELDBUS communication change, Festo will continue to invest and adopt these protocols and implement them into our products. Mechanical drawings and mounting accessories are also continuously being updated to keep up with new products and market trends.”

In summary, the automation industry has seen many changes and will see even more in the years to come. Companies need to adapt new technologies and products to be competitive in Industrie 4.0, and to be prepared for the coming changes in the industry. Festo’s Automation Platform provides new products and communication protocols to the industry that are adaptable, flexible, and convenient. Their solutions gather large amounts of devices, from servo drives to sensors, and provide protocols that ae suitable for major PLC brands, which allows for easy integration and data gathering, ready for the future of industry.

Read Festo’s Seamless Connectivity Part 1 – Products here

For more information visit Festo.ca